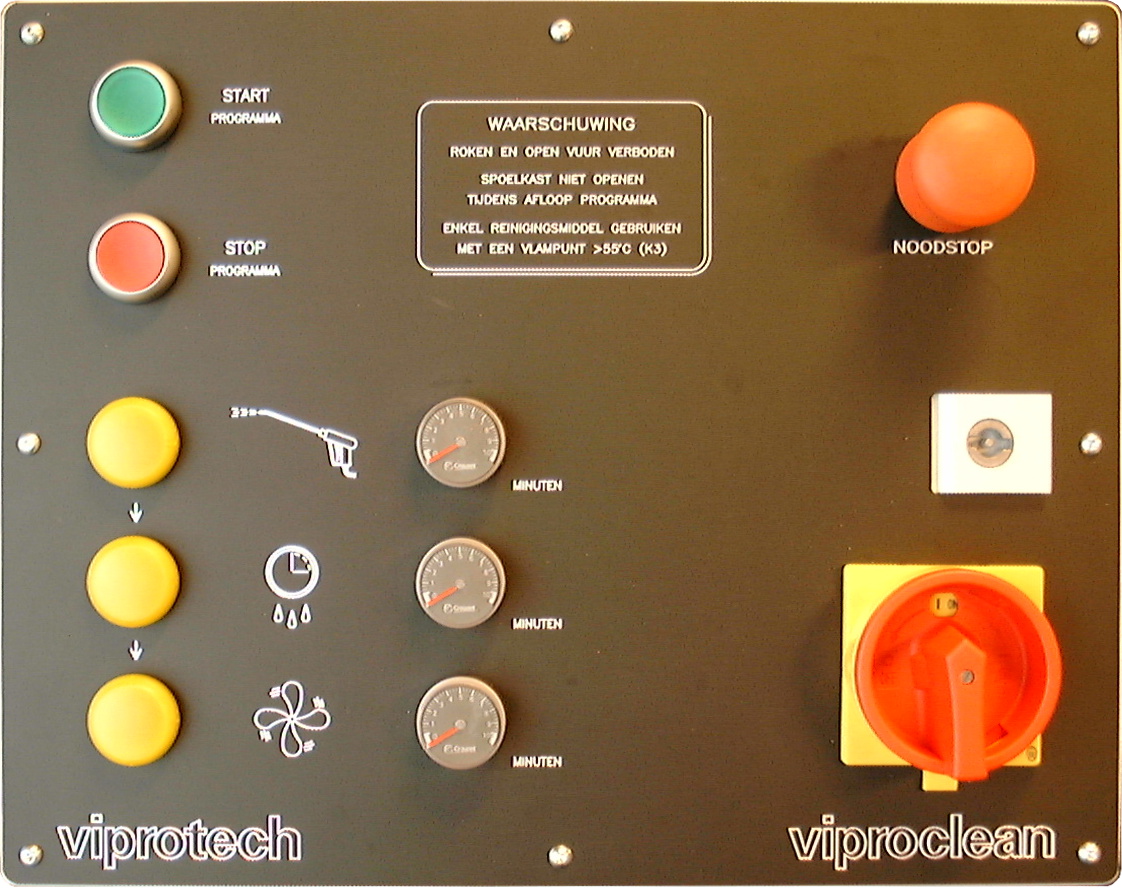

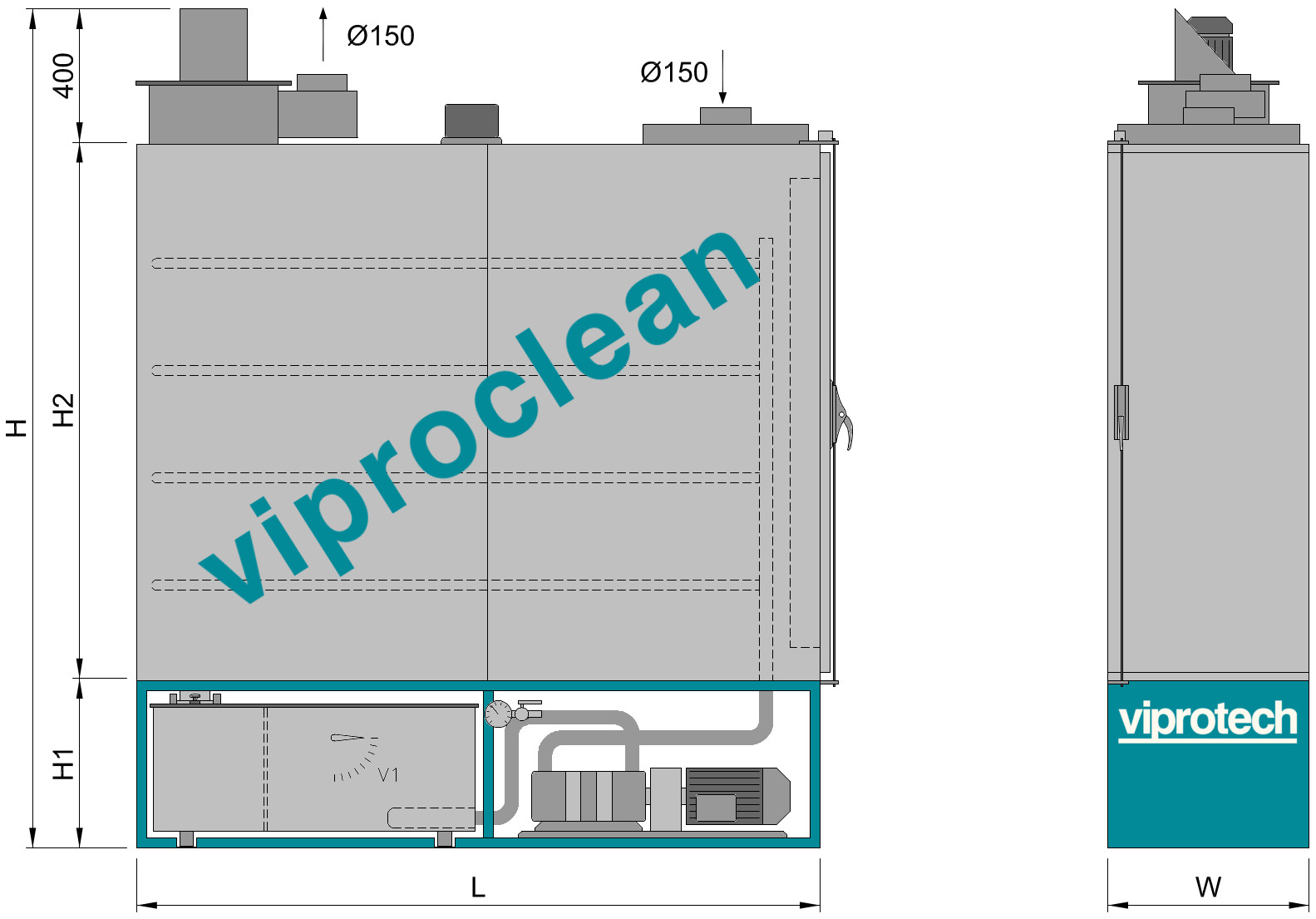

The Viproclean is an economical, full automatic screen wash installation specifically designed for the medium-sized screen printing shop. The stainless steel spray compartment and tubes are equipped with a set of well balanced overlapping high pressure solvent spray nozzles, thoroughly cleaning screens up to a specified maximum size. During the washing cycle the screen is sprayed with solvent. The run-off solvent is flowing back to the solvent tank where it passes though a coarse and two fine filters before entering the solvent pump again. These filters effectively prevent the nozzles from clogging. After the washing cycle there is a pause in which the solvent spray condenses and flows back to the tank. After that, the cabinet ventilation assist in drying the screen and extract solvent fumes. The duration of the washing, delay and ventilation cycle can be set on the control panel. A low pressure inside the spray compartment prevents solvent fumes from escaping when the compartment door is opened. The Viproclean is supplied with a custom sized safety floor (not shown on the picture) which is able to absorb the full tank capacity in case of an accidental leakage. The installation is built in accordance with the latest European health and safety regulations (CE); motors, junction boxes and switches are all explosion proof in accordance with ATEX 95 (EEx-e-II-T3). The cleaning cycle can be started and stopped by pressing a button on the compartment door, allowing the Viproclean’s control panel to be installed in an adjacent room. Characteristics Special Properties Viproclean

Machine details

Machine properties

Technical specifications and dimensions

Maximum screen size 1400 x 1800 1900 x 2300 2150 x 3150

Machine width [W] 600

Machine depth [L] 2150 2650 3500

Machine height [H] 2550 3100 3350

Machine base frame height [H1] 550 600 600

Machine cabinet height [H2] 1600 2100 2350

No. of filters 1x coarse and 2x fine filter 75 micron

Operating pressure 200 to 300 kPa (2 to 3 bar)

Program duration 10 to 15 minutes typical

Electrical connection 400V, 50Hz, 3 phase + N + Pe, 3kW

Our products receive continual updates and improvements to enhance quality and productivity, effectively changing its original specifications. All of the above information is to be considered as indicative. All units are expressed in the metric system. Dimensions are in millimeter [mm] unless stated otherwise.

Viproclean